Looking Into Liquid Flooring? Here’s What to Know About Epoxy and Garage Floor Coatings in the U.S.

Introduction to Liquid Flooring Systems

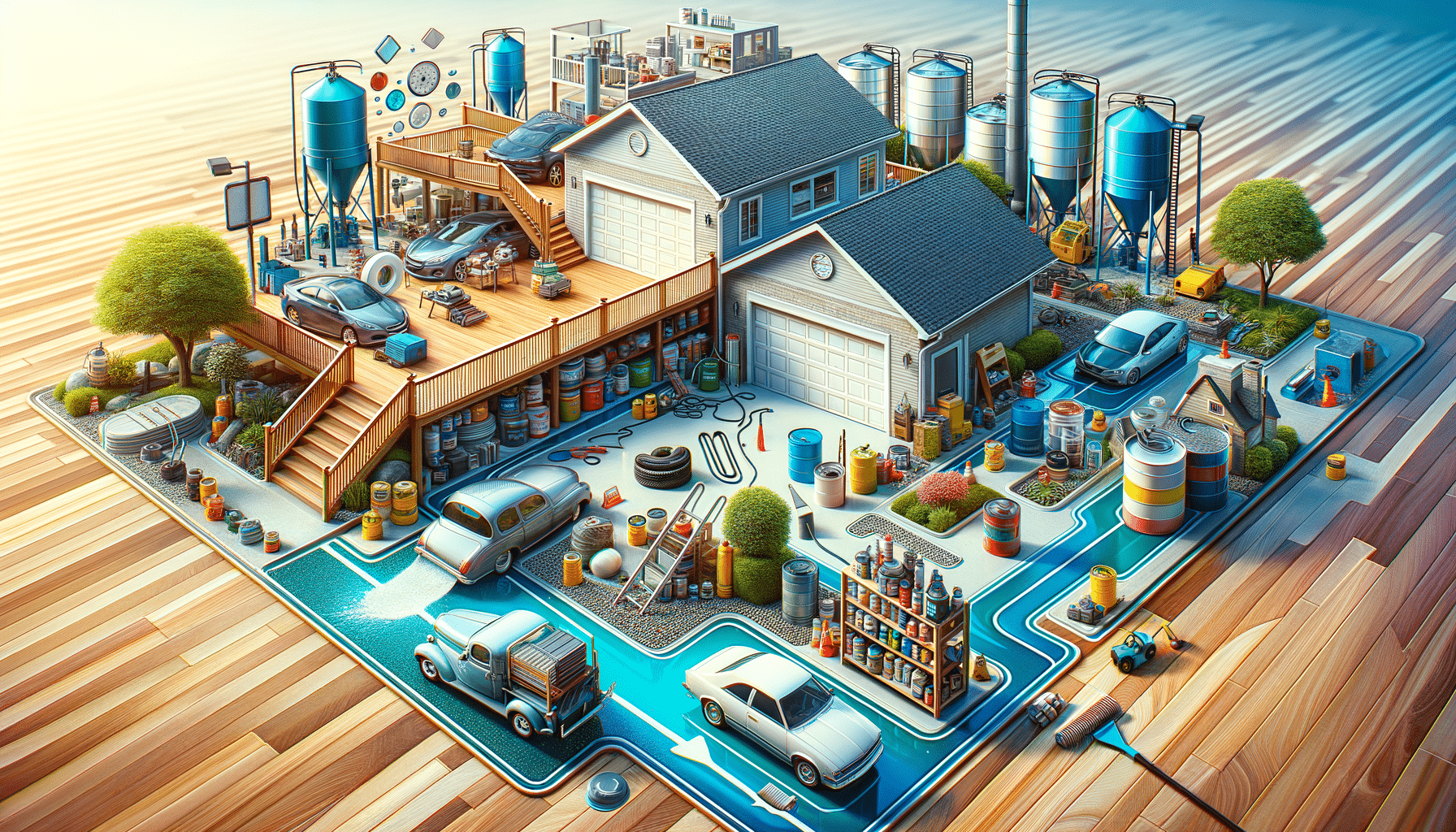

Liquid flooring systems have revolutionized the way we think about floors, offering a seamless and durable finish that is both aesthetically pleasing and highly functional. Among these systems, epoxy flooring stands out due to its versatility and resilience. Liquid flooring systems are increasingly popular in a variety of settings, from industrial warehouses to modern homes. This trend is driven by the need for durable, easy-to-maintain surfaces that also offer a sleek appearance.

These systems are composed of a mix of resins and hardeners that, when combined, create a rigid plastic material. This material bonds extremely well to concrete substrates, making it an ideal choice for environments that demand high performance and longevity. Liquid flooring systems are particularly valued for their resistance to wear and tear, chemical spills, and moisture, which makes them suitable for garages, commercial spaces, and even kitchens.

In addition to their practical benefits, liquid flooring systems offer a wide range of design possibilities. They can be customized with various colors, patterns, and finishes, allowing property owners to achieve a look that complements their aesthetic preferences. As a result, these systems are not only functional but also enhance the visual appeal of any space.

Epoxy Flooring Installation: What It Involves and Where It’s Used

Epoxy flooring installation is a meticulous process that requires careful preparation and execution. The first step involves cleaning and preparing the surface to ensure optimal adhesion. This may include removing existing coatings, repairing cracks, and thoroughly cleaning the floor to remove any dust or debris. Once the surface is prepared, a primer is applied to promote adhesion between the concrete and the epoxy coating.

After the primer has cured, the epoxy mixture is applied in multiple layers to achieve the desired thickness. Each layer must be allowed to cure before the next is applied, ensuring a strong and durable finish. The final step involves applying a topcoat, which adds an extra layer of protection and enhances the floor’s appearance. This topcoat can be customized with different textures and finishes, such as a high-gloss or matte look, depending on the desired aesthetic.

Epoxy flooring is widely used in various settings due to its durability and versatility. It is a popular choice for garages, where it can withstand heavy vehicles and resist oil stains. In commercial spaces, epoxy flooring is valued for its ability to endure high foot traffic and resist chemicals, making it ideal for factories, warehouses, and laboratories. Additionally, its seamless finish makes it easy to clean and maintain, a crucial factor in environments where hygiene is a priority.

Pricing and What to Expect From a Liquid Flooring Contractor

When considering liquid flooring systems, understanding the pricing structure and what to expect from a contractor is essential. The cost of epoxy flooring can vary significantly based on several factors, including the size of the area, the condition of the existing floor, and the type of epoxy system chosen. On average, homeowners can expect to pay between $3 and $12 per square foot for epoxy flooring installation.

Several elements influence the overall cost:

- Surface Preparation: The condition of the existing floor can affect the cost. Floors that require extensive repairs or cleaning will increase the overall expense.

- Type of Epoxy: Different epoxy systems come with varying price tags. High-performance epoxy systems designed for industrial use may cost more than those intended for residential settings.

- Customization: Adding custom colors, patterns, or textures can increase the cost but also enhance the aesthetic appeal of the floor.

When hiring a liquid flooring contractor, it is important to choose a reputable professional with experience in epoxy flooring installation. A reliable contractor will offer a detailed quote, outlining the scope of work and associated costs. They should also provide a timeline for the project and be transparent about any potential challenges that may arise during the installation process.

Ultimately, investing in a liquid flooring system can be a worthwhile decision, offering a durable and attractive solution for a variety of spaces. By understanding the installation process and associated costs, property owners can make informed decisions and achieve the desired results.

Exploring the Benefits of Liquid Flooring Systems

Liquid flooring systems offer numerous benefits that make them an attractive option for both residential and commercial spaces. One of the primary advantages is their durability. These floors are designed to withstand heavy use, making them ideal for areas with high foot traffic or heavy machinery. They are resistant to scratches, stains, and chemicals, which can prolong the lifespan of the floor and reduce maintenance costs.

Another significant benefit is the ease of maintenance. Liquid flooring systems are seamless, which means there are no joints or seams where dirt and grime can accumulate. This makes cleaning a breeze, as spills can be easily wiped away without leaving stains. Additionally, the non-porous nature of these floors prevents the growth of mold and bacteria, contributing to a healthier indoor environment.

In terms of aesthetics, liquid flooring systems offer a wide range of design options. Property owners can choose from various colors, patterns, and finishes to create a customized look that complements their space. This versatility allows for creative expression and can enhance the overall ambiance of a room.

Furthermore, liquid flooring systems are environmentally friendly. Many of these systems are made with low-VOC (volatile organic compound) materials, which means they emit fewer harmful chemicals into the air. This makes them a sustainable choice for those looking to reduce their environmental impact.

Choosing the Right Liquid Flooring System for Your Needs

When selecting a liquid flooring system, it is important to consider the specific needs and requirements of the space. Different environments may have unique demands, and choosing the right system can ensure optimal performance and longevity. Factors to consider include the level of foot traffic, exposure to chemicals, and desired aesthetic.

For industrial settings, a high-performance epoxy system may be necessary to withstand heavy machinery and chemical spills. These systems are designed to provide maximum durability and resistance, making them ideal for factories and warehouses. In contrast, residential spaces may benefit from a decorative epoxy system that offers a balance of aesthetics and functionality.

It is also important to consider the installation process and timeline. Some liquid flooring systems may require longer curing times, which can impact the overall project timeline. Discussing these details with a contractor can help ensure that the chosen system aligns with the project schedule and budget.

Ultimately, the right liquid flooring system can transform a space, offering a durable and attractive solution that meets the specific needs of the environment. By carefully considering the options and working with a reputable contractor, property owners can achieve the desired results and enjoy the benefits of a high-quality flooring system.